15NB Table D & E BS3063 Full Face Gasket, 3mm Conafi Gasket Fibre

BULK DISCOUNT RATES

| Buy 10 - 24 | and pay only $3.39 each |

| Buy 25 or above | and pay only $3.26 each |

| Buy 10 - 24 | and pay only $3.39 each |

| Buy 25 or above | and pay only $3.26 each |

Conafi Flange Gaskets are a great option for general-purpose sealing requirements. These gaskets are a step up from (most types of) rubber in terms of pressure and temperature resistance yet are still quite economical.

The styles and sizes listed on this page are all made to suit BS 3063 Flanges (Table D and/or Table E) and are available in Full Face (with bolt holes).

We also offer this same range of gaskets made from Conafi in 1.5mm thick online.

Conafi is a general-purpose gasket fibre sheet material that is made from a combination of mineral and aramid fibres that are secured with an NBR (Nitrile Butadiene Rubber) binder. Gaskets cut from this quality material offer several benefits, including:

Conafi Gaskets have been engineered to hit the sweet spot between versatility and economy. To achieve this, the material has been produced using only quality ingredients with the result being a gasket material with excellent compatibility with various types of media, fluids and chemicals.

Conafi is highly compatible with:

Good Temperature Resistance.

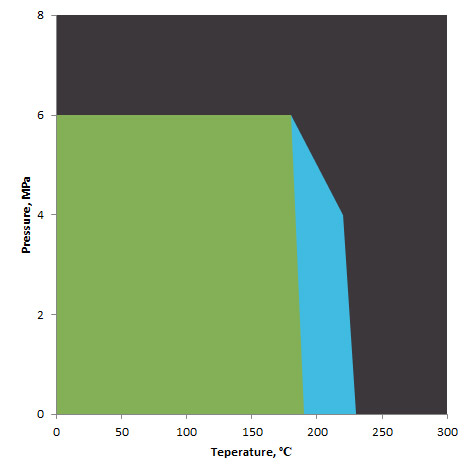

Good Temperature Resistance.Conafi generally withstands sealing applications with temperatures between -30°C and +220°C. Like most gasket materials, the maximum operating temperature of Conafi Gaskets have a direct relationship with the pressure they are sealing.

The chart on the right illustrates this relationship showing that at its maximum pressure rating (6MPa) Conafi should only be used for applications up to about 180°C (this is also true when used to seal steam). Higher temperatures are possible where the operating pressure of the joint is lower.

In addition to Conafi’s ability to handle a wide range of temperatures and media, this material has excellent sealing properties. Many are summarised in the table below with more information available on the attached Conafi Technical Data Sheet.

| Base Materials | Kevlar Aramid Fibres, Mineral Fibres and an NBR Binder |

|---|---|

| Maximum Continuous Operating Pressure | 6 MPa |

| Density | 2 g/cm³ |

| Compressibility | 11.7% (ASTM F 36) |

| Recovery | 58.8% (ASTM F 36) |

| Creep Relaxation | 20.3% (ASTM F 36) |

All Dimensions below are given in millimeters (mm).

| Flange Nominal Bore |

Gasket OD | Gasket ID | Number of Holes |

Hole Diameter |

PCD | Matches Table |

| 15NB | 95 | 21 | 4 | 14 | 67 | E |

| 20NB | 102 | 27 | 4 | 14 | 73 | E |

| 25NB | 114 | 34 | 4 | 14 | 83 | E |

| 32NB | 121 | 43 | 4 | 14 | 87 | E |

| 40NB | 133 | 48 | 4 | 14 | 98 | E |

| 50NB | 152 | 60 | 4 | 19 | 114 | E |

| 65NB | 165 | 76 | 4 | 19 | 127 | E |

| 80NB | 184 | 89 | 4 | 19 | 146 | E |

| 90NB | 203 | 102 | 4 | 19 | 165 | - |

| 100NB | 216 | 114 | 4 | 19 | 178 | - |

| 125NB | 254 | 140 | 8 | 19 | 210 | E |

| 150NB | 279 | 168 | 8 | 19 | 235 | - |

| 200NB | 337 | 219 | 8 | 19 | 292 | - |

| 250NB | 406 | 273 | 8 | 22 | 356 | - |

| 300NB | 457 | 324 | 12 | 22 | 406 | - |

| 350NB | 527 | 381 | 12 | 25 | 470 | E |

| 400NB | 578 | 432 | 12 | 25 | 521 | E |

| 450NB | 641 | 483 | 12 | 25 | 584 | - |

| 500NB | 705 | 533 | 16 | 25 | 641 | E |

| 600NB | 825.5 | 635 | 16 | 29 | 756 | - |

All Dimensions below are given in millimeters (mm).

| Flange Nominal Bore |

Gasket OD | Gasket ID | Number of Holes |

Hole Diameter |

PCD | Matches Table |

| 15NB | 95 | 21 | 4 | 14 | 67 | D |

| 20NB | 102 | 27 | 4 | 14 | 73 | D |

| 25NB | 114 | 34 | 4 | 14 | 83 | D |

| 32NB | 121 | 43 | 4 | 14 | 87 | D |

| 40NB | 133 | 48 | 4 | 14 | 98 | D |

| 50NB | 152 | 60 | 4 | 19 | 114 | D |

| 65NB | 165 | 76 | 4 | 19 | 127 | D |

| 80NB | 184 | 89 | 4 | 19 | 146 | D |

| 90NB | 203 | 102 | 8 | 19 | 165 | - |

| 100NB | 216 | 114 | 8 | 19 | 178 | - |

| 125NB | 254 | 140 | 8 | 19 | 210 | D |

| 150NB | 279 | 168 | 8 | 22 | 235 | - |

| 200NB | 337 | 219 | 8 | 22 | 292 | - |

| 250NB | 406 | 273 | 12 | 22 | 356 | - |

| 300NB | 457 | 324 | 12 | 25 | 406 | - |

| 350NB | 527 | 381 | 12 | 25 | 470 | D |

| 400NB | 578 | 432 | 12 | 25 | 521 | D |

| 450NB | 641 | 483 | 16 | 25 | 584 | - |

| 500NB | 705 | 533 | 16 | 25 | 641 | D |

| 600NB | 825.5 | 635 | 16 | 32 | 756 | - |

| Colour | Green |

|---|---|

| Temperature Resistance | -30°C to +220°C |

| Potable Water Approved | Yes (KTW) |

| Gas Approved | Yes (DVGW) |

| Oxygen Sealing Approved | No |

| Base Materials | Kevlar Aramid Fibres, Mineral Fibres and an NBR Binder |

| Maximum Continuous Operating Pressure | 6 MPa |

| Density | 2 g/cm³ |

| Compressibility | 11.7% (ASTM F 36) |

| Recovery | 58.8% (ASTM F 36) |

| Creep Relaxation | 20.3% (ASTM F 36) |

| SKU | SWM000011P04-3.0 |

|---|