Take a look at the answers we gave to some

of the best and most interesting questions we received

from our customers this month!

| 3 |

I'm after something to use as lagging for my spa heater flue pipe. Any recommendations? |

|

|---|---|---|

|

For this applicatin, if you are after a thin material, we'd suggest our Aluminium Foil Faced Fibreglass.

The cloth itself will handle 260°C continuous (it'll handle higher but the bond between cloth and foil will start to fail) and it'll be better for the outdoor part as it'll have the foil face to protect it from the elements.

.png) |

||

| 4 |

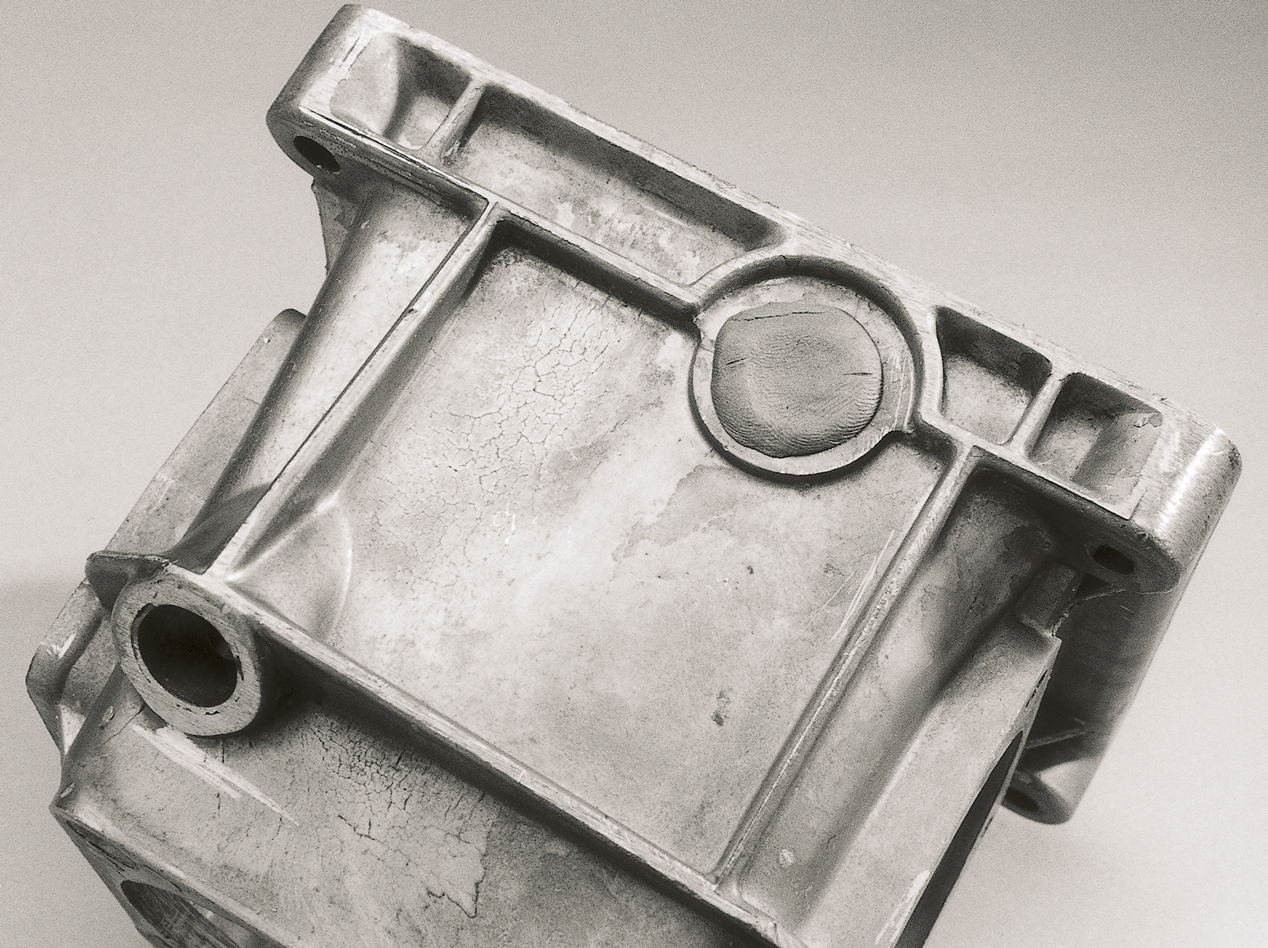

I have a two stroke water cooled motorcycle engine made of aluminium alloy and part of the casing has broken, but is still in one piece and can be refitted in place. Will your aluminium repair stick bond to this metal and be strong enough to seal? |

|

|---|---|---|

|

We think our Aluminium Repair Stick would be perfect. You should have no worries about it bonding to the alloy and it will certainly set hard to seal.

The only potential issue that may arise is temperature. The Aluminium Repair Stick is rated to 120°C continuous. If the temperatures in this application remain under that, it'll be fine. If they're higher, our suggestion would be the Titanium Repair Stick. It is a little more expensive, but it will handle 280°C. .png) |

||

Leave a comment