Welcome to Part 3 of our series of tips and advice for super gluing plastic. This week, we’re going to focus on preparing the plastic surface for bonding.

Welcome to Part 3 of our series of tips and advice for super gluing plastic. This week, we’re going to focus on preparing the plastic surface for bonding.

In our two previous posts, we provided a wealth of information on how to identify what type of plastic you are working with followed by a guide to choosing a super glue that matches your type of plastic. If you missed either of them, you can access them via the links above. Next week, we'll finish the series with a post covering how to best apply the glue to plastic and tips and for getting the very best bond possible (available here). For everyone else, read on.

Why Surface Preparation Matters

We’ll be the first to admit that talking about how to prepare plastic for bonding isn’t exactly the sexiest subject. It’s also a step that gets skipped a lot and this can lead to real problems. Time after time we’ve seen people focus on choosing the right glue yet skip the critical step of making sure it has a chance to succeed.

We’ll be the first to admit that talking about how to prepare plastic for bonding isn’t exactly the sexiest subject. It’s also a step that gets skipped a lot and this can lead to real problems. Time after time we’ve seen people focus on choosing the right glue yet skip the critical step of making sure it has a chance to succeed.

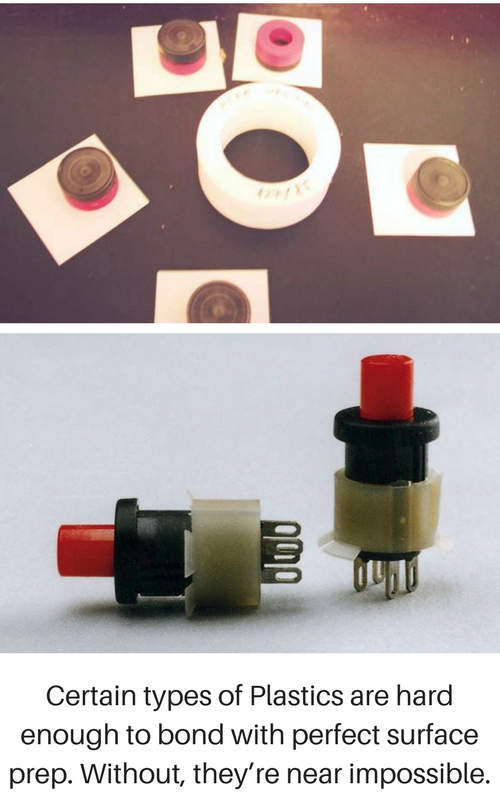

Correct Surface preparation is critical to the success of any adhesive but this is especially true with plastics and super glues. As readers of our two previous posts in this series would know, there’s some types of plastic out there that are extremely hard to bond. PTFE, HDPE, LDPE and PET all meet this definition. No matter what glue you use, failing to prepare the surface of one of these will all but guarantee a weak join or no bond at all.

The other reason that surface preparation is so critical in this area has to do with the nature of super glues. Also known as contact adhesives, liquid adhesives or Cyanoacrylates; Super Glues will stick to anything. This includes any dirt or dust present on the bonding surface, oily residues or other media. Every little bit of glue used to glue dust particles is one less bit dedicated to ensuring a high strength bond for your plastic part.

Put simply, skipping this step can negate all the work you did in glue selection and application. It’s that important.

Cleaning the Plastic

First up is the critically important step of making sure the plastic you’re going to bond is clean, dry and free of any oily or greasy residues. Depending on the exact type of plastic you’re working with, soap, isopropyl alcohol or one of our specialised industrial cleaning sprays may be ideal for this.

First up is the critically important step of making sure the plastic you’re going to bond is clean, dry and free of any oily or greasy residues. Depending on the exact type of plastic you’re working with, soap, isopropyl alcohol or one of our specialised industrial cleaning sprays may be ideal for this.

For general-purpose types plastics, our Surface Cleaner Spray is fast, reliable and very effective. For more sensitive types, we offer our Plastic Cleaner Spray. This has been specially formulated to clean without damaging the underlying plastic surface. Both are made by Weicon, the manufacturer of our industrial super glues, and are therefore highly compatible with each glue in our range.

Once you have cleaned the plastic, dry it thoroughly. Try to use a soft, lint-free cloth here as any loose fibres that are left behind will be happily accepted by the super glue in lieu of sticking to the plastic. Also, once your plastic is clean and dry, try to avoid touching the part you’re going to bond with your bare hands. The natural oil present in skin can interfere with the glue.

Roughen the Surface

If you’re sticking smooth plastic sheet or parts, try to roughen the bonding area a little before using the glue. For most plastics, a light run-over with 120-200 grit sandpaper will do the job but you can also use steel wool or some other abrasive if necessary.

Roughening up smooth surfaces will significantly increase the surface area available to the glue and, thus, lead to higher strength bonds. You only need to do this very lightly, even a slight roughening will have results.

Once you have roughened it, have a quick look to make sure there are no loose fibres or dust on the surface.

If the plastic you are working with already has a rough surface you can safely skip this step. The video below shows our VA 100 being used to glue together some wooden parts. As you’ll see, cleaning is important but there’s no need to rough up the surfaces in this case as they’re already fairly coarse.

We hope you’ve enjoyed this short post on preparing a plastic for super glue. Next week, we’ll be back with information on the best way to apply primers and super glues to plastic.

As always, thanks for reading. If you have any questions at all about super gluing plastic please do not hesitate to contact us and we’ll help in any way we can. Alternatively, if you have any tips of your own, please let us know in the comments.

Other Posts in this Series on Our Best Super Glues for Plastic

Part 1: Tips and Methods for Identifying Different Types of Plastic

Part 2: Choosing a Super Glue for Different Types of Plastic

Part 4: Applying the Glue and Tips for Maximum Bond Strength