Range length.jpg) Welcome to the first of four posts dedicated to helping you choose the best super glue for different types of plastic. We’ll be publishing one per week for the next four weeks.

Welcome to the first of four posts dedicated to helping you choose the best super glue for different types of plastic. We’ll be publishing one per week for the next four weeks.

This week is part 1 and deals with how to identify different types of plastic. After this we’ll cover choosing the best super glue for your plastic (update: Part 2 is now live and can be accessed here), preparing the plastic for bonding (now available here) and applying the glue, along with tips for achieving maximum bond strength (available here).

For those of you who need to super glue plastic now, and don’t really feel like waiting for the next few posts, please do not hesitate to contact us. We’ll be happy to help in the meantime. Alternatively, our comprehensive guide to super glues is also available. It doesn’t focus on plastic exclusively, but does contain a wealth of information that could be very helpful in guiding your glue choice.

Identifying Different Types of Plastic

There are many, many different types of plastic and each behaves differently with adhesives. Some, like rigid PVC, are fairly easy to bond. Others, like polyethylene or, even worse PTFE, are almost (but not quite) impossible. Because of the differences in how each type behaves in conjunction with adhesives, the first step in choosing the best super glue for plastic is to work out what kind of plastic you need to bond.

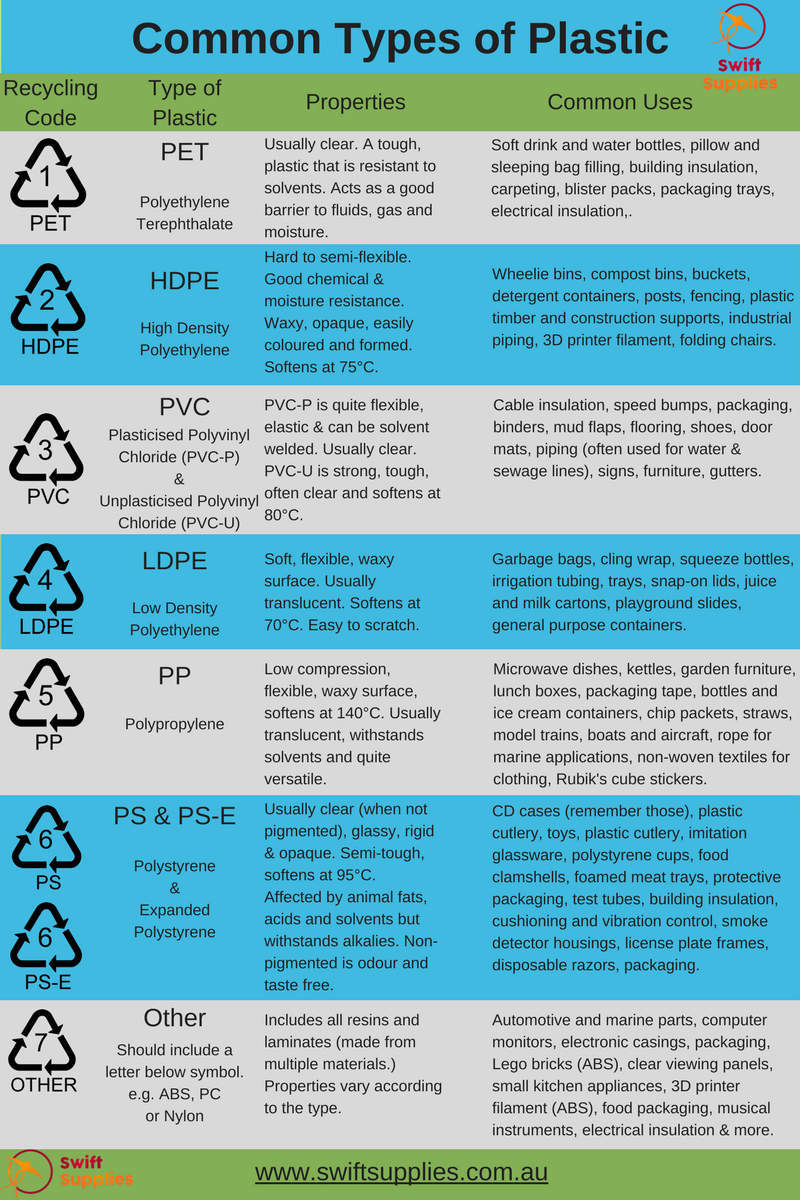

Conveniently, there are several methods that you can use. If the item you need to bond has a recycling code on it, you’re in luck as this can be used. The chart below provides an overview of what each one means.

Other Methods for Identifying Types of Plastic: The Float Test

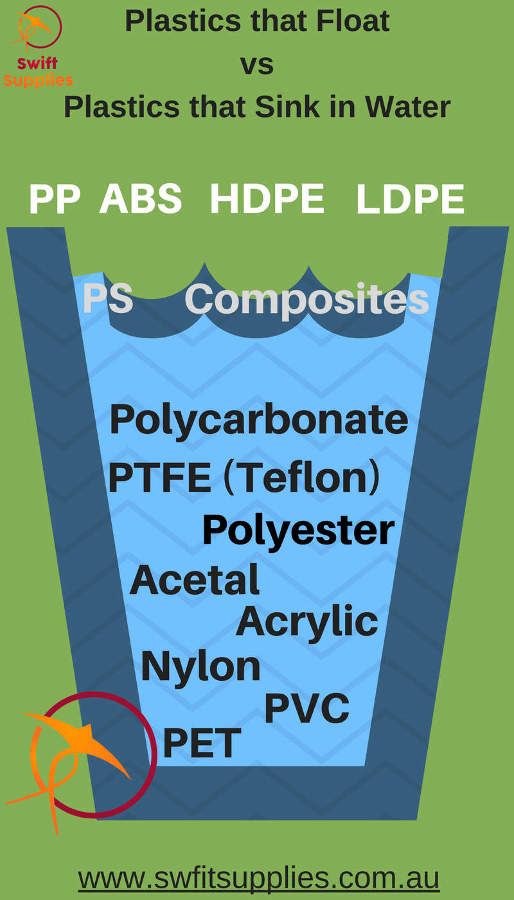

If your item does not have a recycling code, there are still other methods you can use. One of simplest (and least destructive) is to see if it floats. Not all plastics do and, while there are exceptions, seeing if a piece of plastic floats is a pretty good way to work out what kind of plastic it is.

I want to stress that there are exceptions to this (and many plastics will absorb water, changing their behaviour over time), but a general rule of thumb is…

As the above graphic suggests, Polypropylene (PP), ABS and both High and Low Density Polyethylene (HDPE & LDPE) all float. Polycarbonate, PTFE, Polyester, Acetal, Acrylic, Nylon, PVC and PET all sink in water.

Polystyrene and composite materials can go either way depending on their exact construction. Polystyrene foams (like food containers) usually float because of the amount of air locked into the foam which decreases their density. Composites could be almost any combination of one or more plastics so they are impossible to identify using this method.

If you still require further confirmation of exactly what type of plastic you are working with, there are more identification methods you can try. These include…

Flammability / Burn Testing

Flammability / Burn Testing

Plastics in the polyolefin group (High Density Polyethylene (HDPE), Low Density Polyethylene (LDPE) and Polypropylene (PP)) are quite flammable and burn very easily. Be extremely careful when testing these kinds of plastics as molten plastic can drip quite quickly. Taking all prudent safety measures is a must.

PVC and ABS plastics will ignite, but only slightly. When they do they will soften but won’t drip molten plastic the way types in the polyolefin group will.

PET plastic will also ignite only slightly. You will notice that this type of plastic will bubble as it melts.

Colour / Appearance of Flame

Colour / Appearance of Flame

Both polyolefins (HDPE, LDPE & PP) and nylons will give off a blue flame with a yellow tip when ignited. Conveniently, they do not both float so if the flame test is inconclusive, place the plastic in water. Nylon will sink, polyolefins should float.

If the flame is yellow with a green tip the plastic is likely PVC. If it is yellow with dark smoke it is most likely PET or polycarbonate while sooty, dark smoke and a yellow flame usually indicates polystyrene or ABS.

Smell

This is a test of last resort. It should only be considered if every other method is impractical or inconclusive and you simply must know what kind of plastic you are working with. The reason is simple, sniffing plastic fumes really is not healthy and definitely not something you want to engage in on any kind of regular basis. This is even more important if you already suspect the plastic may be PVC. Its fumes are particularly nasty (though I really do stress, none are good). That said, there are differences in the smell given off by the different types of plastic so this can be a way to gather more information on the type you are working with.

PET smells like burnt sugar (something like fairy-floss) while PVC has an acrid smell that is similar to chlorine. Again, I really do stress that smelling the smoke or gas given off by burnt PVC is a really, really bad idea and should be avoided.

ABS and polystyrene both smell like styrene but the ABS has a faint rubbery smell to it.

LDPE and HDPE both smell like candle wax while Polypropylene smells like candle wax but also has a faint scent of paraffin to it.

Conclusion

Hopefully the information here has helped you identify exactly what type of plastic you are working with. Next week, we’ll be back with another post identifying the best glue for each and every type covered here. Everything from common grades like PVC and Nylon through to super glues for notoriously hard to bond plastics like polyethylene and PTFE will be covered. We’ll also explain why identifying the correct plastic matters so much for choosing a super glue.

In the meantime, if you have questions about identifying a specific grade, or other tips that could help fellow readers please do not hesitate to contact us or, alternatively, leave your own tips and tricks in the comments. This post will be all the better for your contributions.

Other Posts in this Series on Our Best Super Glues for Plastic

Part 2: Choosing a Super Glue for Different Types of Plastic

Part 3: Preparing the Plastic Surface for Bonding

Part 4: Applying the Glue and Tips for Maximum Bond Strength

Comments (1)

About this information.

Leave a comment