BULK DISCOUNT RATES

| Buy 6 - 11 | and pay only $20.23 each |

| Buy 12 or above | and pay only $19.70 each |

| Buy 6 - 11 | and pay only $20.23 each |

| Buy 12 or above | and pay only $19.70 each |

Stainless Steel Repair Sticks are a fast, versatile and long-lasting option for repairing and sealing stainless steel and other metal parts. These two-part epoxy putties are manufactured from epoxy resin with stainless steel fillers. They bond well to most surface types, set hard and are NSF approved for use in drinking water applications.

Our Stainless Repair Sticks are very fast curing (35% after just 10 minutes). Once they’re fully cured, they also have excellent physical strength, good temperature resistance (120°C) and withstand most chemicals and media.

Manufactured by Weicon in Germany, our Stainless Steel Repair Sticks are used for a whole range of different applications. Some of the more popular ones and more details on this repair putties capabilities are included below:

.png) NSF Approved for Potable Water Applications.

NSF Approved for Potable Water Applications.Weicon Stainless Steel Repair Sticks have been certified in accordance with NSF/ANSI 61 for use in applications that process drinking (potable) water.

Fully cured Stainless Repair Sticks have a hardness rating of 75 Shore D. To put that in perspective, most hard hats measure about 80 Shore D. The fact it sets this hard means you can machine this putty once it’s cured. More specifically, Stainless Steel Repair Stick can be…

This lets you finish your repair job down to tight tolerances of give the putty an ultra-smooth finish. Since it’s coloured to match stainless, it also provides a pathway to minimising the visibility of any repair work. That said, since it’s an epoxy, Stainless Steel Repair Sticks can be painted over once their fully cured if required.

No Tools Required.

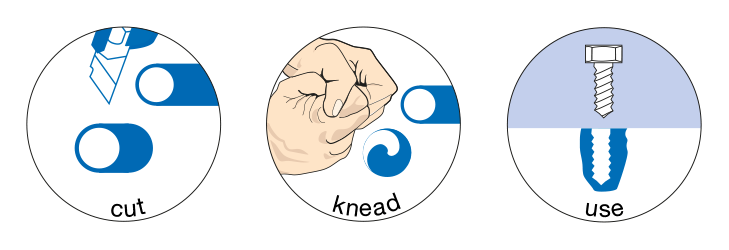

No Tools Required.Like all our Repair Putties, Stainless Repair Stick does not require any tools (unless you count a pair of rubber gloves). Just cut off the amount you want, knead the two parts until they’re a single colour and apply.

That’s it. Repair Stick Stainless Steel will set hard (like metal).

For all the most common uses of Stainless Repair Stick, it needs to stick to a surface to work. You can rely on this epoxy putty to do so as it has excellent compatibility with a variety of different surface types. The most common ones are covered in the table below:

| Metal (e.g. stainless steel, brass, cast iron, aluminium) | Highly Compatible |

|---|---|

| Hard Plastics* (e.g. epoxy laminates, rigid PVC) | Compatible |

| Wood (e.g. oak, beech, spruce, balsa) | Compatible |

| Derived Timber Products (e.g. plywood, MDF) | Compatible |

| Fibre Reinforced Materials (e.g. GFRP, CFRP, Fibreglass) | Compatible |

| Glass, Ceramics | Compatible |

| Stone (e.g. granite, brick, concrete, marble) | Compatible |

| Rubber Elastomers | Not Compatible |

*Performance will vary depending on the exact type of plastic being bonded. Generally, low surface energy plastics will be much harder to bond to then high surface energy (such as rigid PVC).

As you can see, one thing it doesn’t bond well to is rubber so that should be avoided.

To get the best adhesion possible, we recommended giving the bonding surface a good clean before applying the putty. If you’re sticking to a really smooth surface, adhesion will be enhanced by roughening the bonding surface a bit first.

For some applications, it’s important to only use compounds that have good dielectric strength. Since it’s based on filled epoxy, Stainless Steel Repair Stick has good electrical properties. It has a dielectric strength rating of 3 kV/mm (tested in accordance with ASTM D149) and an electrical resistance rating of 5 · 1011 Ω/cm (ASTM D257).

On the chemical resistance front, Stainless Repair Stick is resistant to many common fluids and media; including…

This is just a small sample of the full chemical resistance table. More information on this repair putties capabilities are included on our Stainless-Steel Repair Stick Tech Data Sheet.

This versatile metal repair putty is used in all kinds of applications spanning the DIY, commercial and heavy industrial sectors. Some of the more common uses include:

| Metal (e.g. stainless steel, brass, cast iron, aluminium) | Highly Compatible |

|---|---|

| Hard Plastics* (e.g. epoxy laminates, rigid PVC) | Compatible |

| Wood (e.g. oak, beech, spruce, balsa) | Compatible |

| Derived Timber Products (e.g. plywood, MDF) | Compatible |

| Fibre Reinforced Materials (e.g. GFRP, CFRP, Fibreglass) | Compatible |

| Glass, Ceramics | Compatible |

| Stone (e.g. granite, brick, concrete, marble) | Compatible |

| Rubber Elastomers | Not Compatible |

*Performance will vary depending on the exact type of plastic being bonded. Generally, low surface energy plastics will be much harder to bond to then high surface energy (such as rigid PVC).

| Colour | Light Grey (Once Cured) |

|---|---|

| Continuous Operating Temperature | -50°C to 120°C |

| Short-Term Operating Temperature | 150°C (2 Hours Maximum) |

| Maximum Gap Filling | 15mm |

| Basis | Epoxy Resin with Stainless Steel Fillers |

| Food Grade | Yes (NSF Approved) |

| Potable Water | Yes (NSF Approved) |

| Density | 2 g/cm³ |

| Pot Life (for 25gm at 20°C) | 4 Minutes |

| Handling Strength (35% of Final) | 10 Minutes |

| Mechanical Strength (50% of Final) | 60 Minutes |

| Final Strength (100%) | 24 Hours |

| Shore Hardness | 75 Shore D |

| Dielectric Strength | 3 kV/mm |

| ISSA Reference Number | 75.530.17 (57gm) / 75.530.18 (115gm) |

| IMPA Reference Number | 81 29 69 (57gm) / 81 29 70 (115gm) |

| SKU | SWM000033B01 |

|---|---|

| Brand | Weicon |

Not really. Just make sure it’s clean and free of dirt, dust or grease (especially true in food areas). If you’re sticking to really smooth surfaces and it’s possible, adhesion will be improved if you roughen the bonding area a little first. Just a bit of sandpaper will often do the job here.

Stainless Steel Repair Sticks will be fully cured in about 24 hours. We say about because this depends a lot on the conditions they’re curing in. The 24-hour estimate is based on a 20°C cure environment. Warmer temperatures will speed this up while lower temperatures will extend it. If you’re using the repair sticks for repairs in a cool room or a fridge you will need to turn the equipment off to allow for curing as temperatures below about 6°C may result in little to no cure.

We really should stress as well that these times are for full cure. At 20°C Weicon Stainless Steel Repair Sticks will achieve handling strength (20% cure) in about 10 minutes and be 50% cured (mechanical strength) after 60 minutes.

Only a very tiny bit. Linear shrinkage is less than 1% during the curing process.

Pretty much anything. Really, a butter knife will do the trick here. One thing worth remembering, since pot life is so quick make sure you just cut off and knead the amount you’re going to use immediately. Also, be sure to clean you’re cutting tool as quickly as possible as parts of the putty can stick and cure on it.