One question we get all the time is about the ability of various types of epoxy repair putties to withstand temperature. It makes sense, these versatile putties are often used for repairing pipes, cracked casings or filling holes in objects where temperature is a concern.

One question we get all the time is about the ability of various types of epoxy repair putties to withstand temperature. It makes sense, these versatile putties are often used for repairing pipes, cracked casings or filling holes in objects where temperature is a concern.

While the answer is usually pretty simple, we’ve noticed there’s a lot of bad information out there. Truth is, any epoxy putty worth its salt will be able to handle at least some temperature. As a result, many of the putties we’ve seen that proclaim to be heat resistant, only offer standard temperature resistance.

The purpose of this post is to try to clarify exactly what you should expect from normal epoxy putties, and high temperature ones. We’re going to focus on our own range of products, but the information will apply to many others.

We’ve broken this post up into sections to make it a little more relevant. The first talks about what we call Epoxy Repair Sticks. These are small(ish), 2-part epoxy resin putties that set hard. There’s many different types (we have 9 ourselves) and they offer different levels of material compatibility, heat resistance, cure time and more. You’ll usually find these in 56gm or 115gm packs.

The second part talks about larger epoxy putties. These are usually based on epoxy resin and are 2-part products. Mix the two together and they’ll set hard. They’re used for repairing larger parts, coating surfaces to bond them together or to enhance their properties (like abrasion resistance). Again, they have different tolerances to heat. You’ll usually find them in 0.5kg, 1kg or 2kg kits (though even larger ones are available).

We hope this post helps you find the right temperature resistant epoxy for your job. If you’ve still got questions, we’ll be happy to help. Don’t hesitate to contact us.

Epoxy Putties with good temperature resistance for small jobs.

Epoxy Putties with good temperature resistance for small jobs.

If you need a putty for covering small gaps, filling holes, repairing cracks or bonding; repair sticks are a great choice. Each type is made from epoxy resin with a different kind of filler. They can all be kneaded by hand and set hard. The exact degree of hardness varies, but none remain soft or flexible once they’re fully set.

Epoxy Repair Stick Putties are the most common type of epoxy putties out there. They’re used in all kinds of different jobs from automotive repair work to marine, hospitality, agriculture and general DIY work.

Like we said earlier, every epoxy putty has some heat resistance. Once they’re cured, every single one of our different types of epoxy repair stick putties will handle at least 120°C on a continuous basis, as well as short-term exposure (usually defined as no more than about 2 hours at a time) to up to 150°C. Some can handle even higher amounts of heat though, here’s the breakdown:

| Type of Repair Stick | Continuous Heat Resistance |

Short-Term Heat Resistance |

Basis |

|---|---|---|---|

| Aluminium | -50°C to +120°C | +150°C | Epoxy Resin with Aluminium Fillers |

| Aqua | -50°C to +120°C | +150°C | Epoxy Resin with Ceramic Fillers |

| Concrete | -50°C to +120°C | +150°C | Epoxy Resin with Ceramic Fillers |

| Copper | -50°C to +120°C | +150°C | Epoxy Resin with Copper Fillers |

| Plastic | -50°C to +120°C | +150°C | Epoxy Resin with Plastic Fillers |

| Stainless Steel | -50°C to +120°C | +150°C | Epoxy Resin with Stainless Steel Fillers |

| Steel | -50°C to +120°C | +150°C | Epoxy Resin with Metal Fillers |

| Titanium | -50°C to +280°C | +300°C | Epoxy Resin with Titanium Fillers |

| Wood | -50°C to +120°C | +150°C | Epoxy Resin with Mineral Fillers |

As you can see there's one clear stand-out; our Titanium Repair Stick. This product has been designed to provide very good heat resistance and will handle 280°C continuously plus short-term spikes to 300°C. Repair Stick Titanium also sets very hard and is extremely tough. It withstands extreme abrasion and sticks very well to most types of material (especially metals). If you're looking for a small(ish) kit of heat resistant repair putty that can handle over 120°C on a continuous basis, our Titanium Filled Epoxy Repair Stick is a great choice.

The video below provides a little more information on this high-quality epoxy putty and shows how it can be used.

If your job doesn't require quite that amount of temperature resistance, your choices are a lot more varied. At this point, considerations about cure time, material compatibility, colour after curing (though they can all be painted) and more come into play. Below is a summary of some of the main properties of each of our remaining types of epoxy repair stick. Links to each style follow where you can find even more information.

| Repair Stick Type | Aluminium | Aqua | Concrete | Copper | Plastic | Stainless Steel |

Steel | Wood |

|---|---|---|---|---|---|---|---|---|

| Metal (e.g. stainless steel, brass, cast iron, aluminium) | ++ | ++ | + | ++ | + | ++ | ++ | + |

| Hard Plastics* (e.g. epoxy laminates, rigid PVC) | + | ++ | + | + | ++ | + | + | + |

| Wood (e.g. oak, beech, spruce, balsa) | + | + | + | + | + | + | + | ++ |

| Derived Timber Products (e.g. plywood, MDF) | + | + | + | + | + | + | + | ++ |

| Fibre Reinforced Materials (e.g. GFRP, CFRP, Fibreglass) | + | + | + | + | ++ | + | + | + |

| Glass, Ceramics | + | ++ | + | + | + | + | + | + |

| Stone (e.g. granite, brick, concrete, marble) | + | ++ | ++ | + | + | + | + | + |

| Rubber Elastomers | - | - | - | - | - | - | - | - |

++ = Highly Compatible

+ = Compatible

- = Not Compatible

*Performance will vary depending on the exact type of plastic being bonded. Generally, low surface energy plastics will be much harder to bond to than high surface energy (such as rigid PVC).

| Repair Stick Type | Aluminium | Aqua | Concrete | Copper | Plastic | Stainless Steel | Steel | Wood |

|---|---|---|---|---|---|---|---|---|

| Pot Life In Minutes (25gm @ 20°C) | 4 | 15 | 6 | 3 | 20 | 4 | 4 | 15 |

| Handling Strength in Minutes (35%, 20°C) | 10 | 30 | 15 | 10 | 40 | 10 | 10 | 45 |

| Mechanical Strength in Minutes (50%, 20°C) | 60 | 60 | 60 | 60 | 180 | 60 | 60 | 60 |

| Final Strength in Hours (100%, 20°C) | 24 | 24 | 24 | 24 | 36 | 24 | 24 | 24 |

| Pressure (DIN 53281-83) N/mm² | 75 | 65 | 80 | 80 | 65 | 75 | 75 | 70 |

| Shore Hardness D | 75 | 65 | 80 | 80 | 65 | 75 | 75 | 70 |

| Average Tensile Shear Strength After 7 Days @ 20°C (DIN 53283) N/mm² |

Aluminium (Sandblasted) |

Steel Sandblasted) |

Concrete | Copper (Sandblasted) |

PVC (Sanded) |

Stainless (Sandblasted) |

Steel (Sandblasted) |

Beech (Sanded) |

| 4.2 | 6.2 | 4.8 | 4.8 | 2.4 | 3.9 | 4.1 | 6.2 | |

| Special Features / Approvals | Excellent For Aluminium |

Cures Underwater |

Matches Concretes Appearance |

NSF Approved |

NSF Approved |

NSF Approved | NSF Approved |

Same Density As Wood |

NSF Approved = Clearance Certificate for Direct Use In The Food Industry according to NSF/ANSI (Standard 61).

More Information on our Epoxy Repair Stick Putties

More information on each of the individual grades of Weicon Epoxy Repair Sticks can be found on their respective product pages (linked via the images below). Alternatively, please do not hesitate to contact us here at Swift Supplies with any questions you have about our repair stick range. We've been working with these for years now and we are very happy to assist.

Temperature resistant Epoxy Putties for larger jobs.

The repair stick range of epoxy putties is very versatile. They can be used for a whole range of different jobs and applications. There is one area where they fall down though and that has to do with their size.

The repair stick range of epoxy putties is very versatile. They can be used for a whole range of different jobs and applications. There is one area where they fall down though and that has to do with their size.

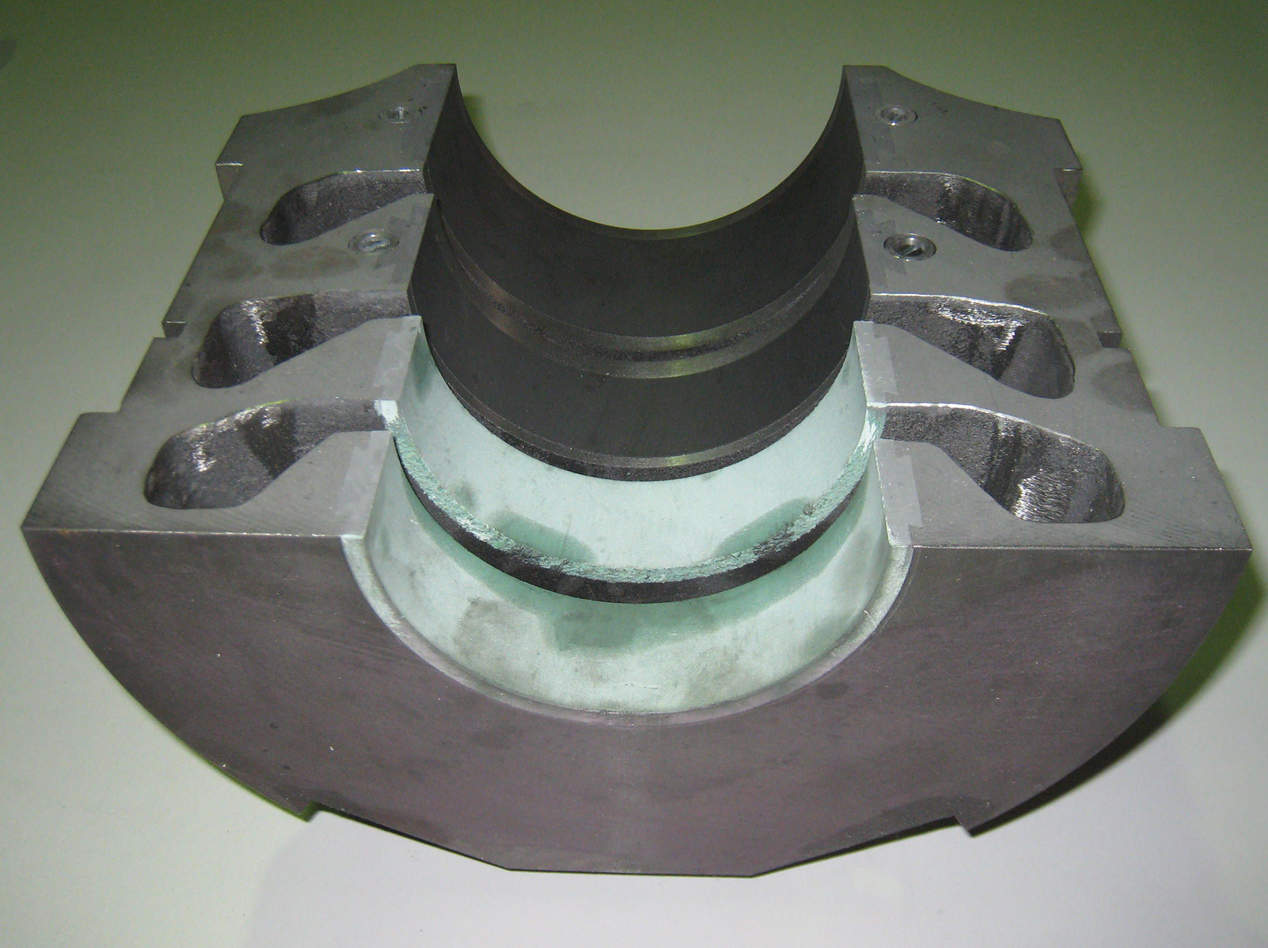

Turns out, when it comes to epoxy putties, size matters. If you’re rebuilding a large propeller shaft, repairing a cracked pump casing or balancing a large armature, you’re going to need a fair amount of putty. You could combine 115gm repair sticks to get there, but other options do exist.

For these larger applications, we offer our Epoxy Plastic Metal range. This selection of professional grade epoxy compounds includes many different grades for rebuilding, filling, coating, bonding and more. In this section, I’ll breakdown the difference between each with a focus on those that will offer the best heat resistance.

Epoxy Resin Putty: A versatile compound with good temperature resistance.

The rest of this section will talk about our various types of epoxy plastic metal but before we get into those, I wanted to mention our Epoxy Resin Putty.

In many ways, it’s like a super-sized repair stick. It is a two part putty with a 1:1 mix ratio. This putty will bond to most materials and is very easy to use. It can be kneaded by hand and sets very quickly (full cure is only about 3 hours). Once set it is very strong and can be drilled, tapped, sanded or painted over. One of its best features; it withstands up to 200°C.

Below is a brief summary of the specifications of our Epoxy Resin Putty. It’s available in 100gm, 400gm or 800gm kits.

| Continuous Operating Temperature | -35°C to 200°C |

|---|---|

| Colour (After Curing) | Green |

| Basis | Epoxy Resin and Mineral Fillers |

| Mix Ratio | 1:1 |

| Pot Life for 200gm of Material @ 20°C | 30 Minutes |

| Viscosity of the Mixture | Pasty |

| Curing Temperature | +6°C to +40°C |

| Maximum Layer Thickness (Per Application) | 15mm |

| Mechanical Strength (50% of Final) | 2 Hours (When Curing At 20°C) |

| Final Strength (100% Cured) | 3 Hours (When Curing At 20°C) |

| Mean Compressive Strength @ 25°C | 80 MPa (DIN 53281-83) |

| Mean Tensile Strength @ 25°C | 30 MPa (DIN 53281-83) |

| Mean Flexural Strength @ 25°C | 56 MPa (DIN 53281-83) |

| Shore Hardness @ 25°C | 87 Shore D |

| Shrinkage While Curing | 0.005% |

| Dielectric Strength | 14 kV/mm (IEC 60.243) |

Epoxy Plastic Metal Products: Resins and Putties for Repair, Production and Maintenance.

Our range of Plastic Metal epoxies is even more comprehensive than our repair sticks. All up, there’s 16 different types to choose from. There’s a great deal that sets each one apart, but there’s also a lot that they each have in common. Before getting into the differences, I want to quickly cover the shared characteristics of each grade in the Weicon Plastic Metal range.

Common Attributes of different types of plastic metal.

Common Attributes of different types of plastic metal.

- Two-part epoxy resin systems.

- Metal or Mineral Filled.

- Extremely resistant to aggressive media and chemicals.

- Pressure resistant.

- Wear resistant, even with high degrees of abrasive force.

- Good residual elasticity and impact resistance.

- Available in larger kits (ranging from 0.5kg to >10kg).

Differences between the grades.

Of course, there's a reason that there's 16 different types of plastic metal. Each grade does offer it's own unique blend of features and benefits. The table below highlights these with a focus on the best types of epoxy plastic metal for high temperatures.

| Type of Plastic Metal Epoxy |

Basis | Properties | Temperature Resistance |

Viscosity of the Mixture (MPa) |

Full Cure (hours) |

Colour (After Cure) |

Compressive Strength |

|---|---|---|---|---|---|---|---|

| Weicon A | Steel Filled | Pasty | -35°C to +120°C | 1,000,000 | 24 | Dark Grey | 80 MPa |

| Weicon B | Steel Filled | Viscous | -35°C to +120°C | 200,000 | 24 | Dark Grey | 110 MPa |

| Weicon BR | Bronze Filled | Pasty | -35°C to +120°C | 650,000 | 24 | Bronze | 95 MPa |

| Weicon C | Aluminium Filled |

Liquid, High Temp. |

-35°C to +220°C | 25,000 | 48* | Grey | 140 MPa |

| Weicon F | Aluminium Filled |

Pasty | -35°C to +120°C | 880,000 | 24 | Aluminium | 61 MPa |

| Weicon F2 | Aluminium Filled |

Viscous | -35°C to +120°C | 200,000 | 24 | Aluminium | 43 MPa |

| Weicon HB 300 | Steel Filled | Pasty, High Temp. |

-35°C to +200°C (280°C Short-Term) |

1,700,000 | 24 | Dark Grey | 100 MPa |

| Weicon Ceramic BL |

Mineral Filled | Liquid, Extremely Wear Resistant |

-35°C to +180°C | 6,000 | 24 | Blue | 85 MPa |

| Weicon Ceramic W |

Mineral Filled | Pasty, Extremely Wear Resistant |

-35°C to +200°C (260°C Short-Term*) |

600,000 | 48* | White | 140 MPa |

| Weicon SF | Steel Filled | Pasty, Fast Cure | -35°C to +90°C | 800,000 | 6 | Dark Grey | 52 MPa |

| Weicon ST | Metal Filled | Thixotropic, Can Be Applied with a Spatula |

-35°C to +120°C | 550,000 | 24 | Grey | 80 MPa |

| Weicon TI | Titanium Filled | Pasty, Wear Resistant |

-35°C to +200°C (260°C Short-Term*) |

550,000 | 48* | Grey | 105 MPa |

| Weicon UW | Mineral Filled | Pasty, Cures Underwater |

-35°C to +120°C | 670,000 | 24 | White | 60 MPa |

| Weicon WP | Ceramic Filled | Pasty, Wear Resistant |

-35°C to +120°C | 900,000 | 96 | Grey | 51 MPa |

| Weicon WR | Steel Filled | Liquid, Wear Resistant |

-35°C to +120°C | 20,000 | 24 | Black | 110 MPa |

| Weicon WR2 | Mineral Filled | Pasty, Wear Resistant |

-35°C to +120°C | 560,000 | 24 | Dark Grey | 71 MPa |

*Can be machined after 16 hours at room temperature (+20°C/+68°F), After 48 hours at room temperature, temper-curing in four steps (3 h +50°C/+122°F, 2 h +90°C/+194°F, 2 h +130°C/+266°F, 1 h +170°C/+338°F). After temper – curing a permanent temperature resistance of +200°C (+392°F) is reached.

A quick note, not all of these are currently in stock at Swift Supplies. We do have access to them all and are adding each to our range but, since they come from Germany, this will likely take some time. For the grades we don't yet have, we've included a link to Weicon's site so you can easily find more information on it. If a particular grade looks like the exact solution you need, and we don't yet have it, we really do encourage you to contact us and let us know. We'll be happy to bring it in for you with one of our very-regular shipments from Germany.

Which Heat Resistant Epoxy Putty Is Right for You?

At this point it is clear that almost all types of epoxy repair putty will withstand some amount of heat once they're fully cured. Therefore, finding the right one for your job really comes down to how much heat the epoxy needs to withstand, what you need the putty to do, how much you need and other application specific considerations.

At this point it is clear that almost all types of epoxy repair putty will withstand some amount of heat once they're fully cured. Therefore, finding the right one for your job really comes down to how much heat the epoxy needs to withstand, what you need the putty to do, how much you need and other application specific considerations.

Obviously, there's no way every combination can be accounted for here. Instead, listed below, are some of our best heat resistant putties for common jobs. If these don't quite fit what you need, don't hesitate to contact us here at Swift Supplies so we can provide more personalised assistance in finding the best epoxy putty for your application.

Heat Resistant Epoxy Putty for Small-Scale Repair Work: Titanium Repair Stick

Heat Resistant Epoxy Putty for Small-Scale Repair Work: Titanium Repair Stick

Available in either 57gm or 115gm packs, Weicon Titanium Repair Stick is ideal for heat resistant, tough, long lasting repair work. This grade is made with titanium filled epoxy resin, can be mixed by hand, and sets very hard. Most impressively, it also withstands exposure to up to 280°C long-term and up to 300°C for short periods of no more than 2 hours.

You can read more about our Titanium Repair Stick here.

Heat Resistant Putty for Larger Scale Work: Epoxy Resin Putty

Heat Resistant Putty for Larger Scale Work: Epoxy Resin Putty

Weicon Epoxy Resin Putty is an extremely versatile compound that can be kneaded by hand and sets hard. This product is made from mineral filled epoxy and bonds well to most types of surface. It is very fast curing (3 hours for full cure) and offers excellent resistant to temperature once its set. Epoxy Resin Putty will handle ongoing exposure to temperatures up to 200°C.

This putty is available in 100gm, 400gm or 800gm kits. You can read more about it over on its product page.

Heat Resistant Epoxy Compound for Large Scale, High Stress Work: Epoxy Plastic Metal HB 300

Heat Resistant Epoxy Compound for Large Scale, High Stress Work: Epoxy Plastic Metal HB 300

An extremely tough, hard-wearing putty; HB 300 is perfect for high heat, high stress industrial applications. This epoxy compound is made from steel filled epoxy resin and can be used for bonding, filling, lining, sealing and rebuilding damaged components. It sets to form an extremely hard and abrasion resistant mass that withstands ongoing exposure to 200°C and short-term spikes to 280°C.

HB 300 is available in 1kg kits. You can read more about its capabilities and the areas it is often used in here.

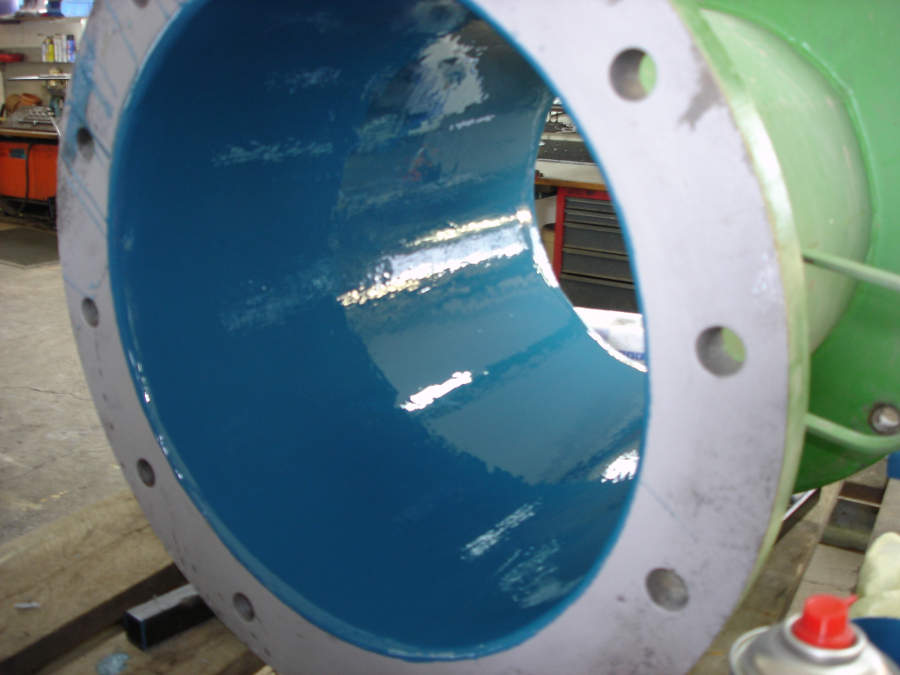

Heat Resistant Epoxy Coating: Plastic Metal Ceramic BL

Heat Resistant Epoxy Coating: Plastic Metal Ceramic BL

Ceramic BL is a liquid, 2-part epoxy that is usually used for lining highly stressed surfaces and components. This epoxy has excellent resistance to abrasion and can be brushed onto a surface. It also offers excellent heat resistance. Ceramic BL will withstand temperatures up to 180°C.

This high quality surface coating epoxy is available in 500gm and 2kg kits. It's coming (very) soon to Swift Supplies but, in the meantime, you can read a lot more about it over on the official Weicon site.

More Information

We really hope you've found this post on our heat resistant epoxy putties useful. We'll keep updating it as our range expands or more information comes to hand. Our greatest source of inspiration for new posts (and updating old ones) is your questions. If you do have other questions about any of our epoxies, or any other product in our quickly-expanding range, please do let us know.

We love being able to help find the best solution for tricky applications and use your questions to drive new product additions, and posts like this to help others. If you have a question, want more information, or have experience to share, please don't hesitate to let us know either via the comments below or by contacting us. We'd love to hear from you.

Comments (2)

Filler to be powder-coated

Swift Supplies response

release agent

Swift Supplies response

Leave a comment