Structural Acrylic Adhesives are 2 Part glues characterised by their high bond strength, wide ranging material compatibility. As the name suggests, they are used for demanding structural bonding applications so correct type selection is crucial.

This guide covers some of the different capabilities of our various types and introduces our new structural acrylic adhesive comparison chart which can help make selection easier.

Material Types that can be Bonded with Acrylic Adhesives.

One of the main benefits of this type of glue is material compatibility. Within our range of acrylic adhesives, you'll find products that can bond types of materials almost no other adhesive can handle. Generally speaking, acrylic adhesives work well with metals, glass, ceramics, composites and many types of plastics.

One of the main benefits of this type of glue is material compatibility. Within our range of acrylic adhesives, you'll find products that can bond types of materials almost no other adhesive can handle. Generally speaking, acrylic adhesives work well with metals, glass, ceramics, composites and many types of plastics.

For some low energy substrates (e.g. Polyethylene, Polypropylene, Polyamide, PTFE) you'll want to choose a particular type.

The table below provides a snapshot of some of our glues shear strength ratings for various material types. There's a lot more materials listed on the full chart.

Acrylic Adhesives Average Strength to Metals

| Adhesive | Aluminium | Steel | Stainless Steel |

|---|---|---|---|

| RK-1300 | 20 N/mm² | 25 N/mm² | 25 N/mm² |

| RK-1500 | 20 N/mm² | 25 N/mm² | 30 N/mm² |

| RK-7000 | 20 N/mm² | 23 N/mm² | 22 N/mm² |

| RK-7100 | 20 N/mm² | 23 N/mm² | 22 N/mm² |

| RK-7200 | 8 N/mm² | 18 N/mm² | 18 N/mm² |

| RK-7300 | 5 N/mm² | 5 N/mm² | 4 N/mm² |

| PE-PP 45 | 14 N/mm² | 17 N/mm² | 16 N/mm² |

| Plastic-Bond | 20 N/mm² | 23 N/mm² | 22 N/mm² |

Acrylic Adhesives Average Strength to Plastics (Table 1)

| Adhesive | Polycarbonate PC |

Acrylic PMMA |

ABS | Rigid PVC | Fibreglass GFK |

Carbon Fibre CFK |

Polyamide 6.6 |

|---|---|---|---|---|---|---|---|

| RK-1300 | 10 N/mm² | 9 N/mm² | 6 N/mm² | 7 N/mm² | 16 N/mm² | 24 N/mm² | 2 N/mm² |

| RK-1500 | 10 N/mm² | 8 N/mm² | 6 N/mm² | 11 N/mm² | 20 N/mm² | 27 N/mm² | 3 N/mm² |

| RK-7000 | 11 N/mm² | 9 N/mm² | 7 N/mm² | 12 N/mm² | 21 N/mm² | 22 N/mm² | 1 N/mm² |

| RK-7100 | 12 N/mm² | 9 N/mm² | 7 N/mm² | 12 N/mm² | 21 N/mm² | 22 N/mm² | 1 N/mm² |

| RK-7200 | 7 N/mm² | 9 N/mm² | 7 N/mm² | 8 N/mm² | 9 N/mm² | 12 N/mm² | 2 N/mm² |

| RK-7300 | 6 N/mm² | 6 N/mm² | 8 N/mm² | 11 N/mm² | 7 N/mm² | 7 N/mm² | 3 N/mm² |

| PE-PP 45 | 6 N/mm² | 7 N/mm² | 11 N/mm² | 14 N/mm² | 17 N/mm² | 16 N/mm² | 6 N/mm² |

| Plastic-Bond | 11 N/mm² | 9 N/mm² | 7 N/mm² | 12 N/mm² | 21 N/mm² | 22 N/mm² | 1 N/mm² |

Acrylic Adhesives Average Strength to Plastics (Table 2)

| Adhesive | Poloxymethylen POM |

Polyethlene High Density HDPE |

Polypropylene PP |

PTFE | EPDM Rubber |

|---|---|---|---|---|---|

| RK-1300 | - | - | - | - | - |

| RK-1500 | - | - | - | - | - |

| RK-7000 | - | - | - | - | - |

| RK-7100 | - | - | - | - | - |

| RK-7200 | - | - | - | - | - |

| RK-7300 | 5 N/mm² | 5 N/mm² | 6 N/mm² | 2 N/mm² | 1 N/mm² |

| PE-PP 45 | 2 N/mm² | 7 N/mm² | 8 N/mm² | - | - |

| Plastic-Bond | - | - | - | - | - |

Types of Acrylic Adhesive Dosing Systems.

All of our acrylic adhesives are 2-part glues however the way they are mixed and applied is different. Within our range, there are three different types of dosing represented. These are explained a little below.

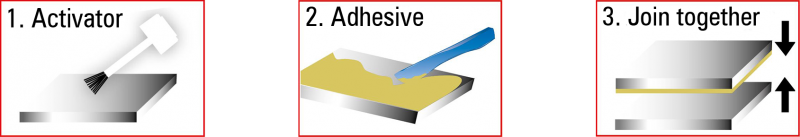

No-Mix Process.

The No MIx system is employed by our RK-1300 and RK-1500 Acrylic Glues. This procedure is particularly well suited for manufacturing processes with staggered assembly as it results in practically no pot life.

Simply apply the activator to one surface and leave for the allotted time. Apply the adhesive to the other surface. Join.

Easy-Mix Dosing System.

The Easy-Mix system is used by RK-7000, RK-7100, RK-7200, RK-7300 and PE-PP (though the latter uses different equipment).

The Easy-Mix system is used by RK-7000, RK-7100, RK-7200, RK-7300 and PE-PP (though the latter uses different equipment).

It works through the use of a dispensing gun and a mixing nozzle. In this process, the adhesive is pushed into the nozzle in the correct ratios and mixed as it travels through so that it reaches the bonding surface already mixed.

The RK adhesives that use this system all work with our D50 Dispensing Gun and the Quadro Mixing Nozzles.

Our PE-PP 45 uses it's own dispensing gun and nozzles.

A + B Procedure.

This is the most manual process represented here. Plastic Bond Acrylic Glue uses this system (though it can be dispensed with the quadro mixing nozzle which is sold separately).

This is the most manual process represented here. Plastic Bond Acrylic Glue uses this system (though it can be dispensed with the quadro mixing nozzle which is sold separately).

Using the A + B method with Plastic-Bond is easy. Simply reject the first centimetre of the dosed bead. Mix the product thoroughly on a surface. Apply adhesive mixture quickly to only one of the surfaces to be bonded. Join both surfaces immediately afterwards.

Other Attributes Impacting Material Selection.

Though what you are bonding is often the first thing you think about when choosing a glue, other factors do come into play as well.

These can include everything from Viscosity / Nature, Gap Bridging Capacity and Colour to Temperature Resistance, Pot Life and Cure Times.

The table below provides these details on each of our main types of acrylic adhesive.

| Adhesive | Nature | Colour | Pot Life @ 20°C |

Max. Gap | Temp. Resistance |

Full Cure |

|---|---|---|---|---|---|---|

| RK-1300 | Pasty | Beige | - | 0.4mm1 | -50°C | +130°C | 24 Hours |

| RK-1500 | Liquid | Yellowish Transparent |

- | 0.4mm1 | -50°C | +130°C | 24 Hours |

| RK-7000 | Viscous | Cream | 15 MIn. | 0.1mm - 5mm | -55°C | +125°C | 12 Hours |

| RK-7100 | Viscous | Cream | 5 Min. | 0.1mm - 5mm | -55°C | +125°C | 12 Hours |

| RK-7200 | Viscous | Transparent | 1 - 2 Min. | 0.1mm - 2mm | -40°C | +120°C | 6 Hours |

| RK-7300 | Pasty | Translucent Creamy |

8 Min. | 0.25mm - 1mm | -55°C | +100°C | 24 Hours |

| PE-PP 45 | Pasty | Yellowish Transparent |

2 - 3 Min. | 0.25mm - 1mm | -50°C | +80°C | 12 Hours |

| Plastic-Bond | Viscous | Cream | 15 Min. | 0.1mm - 5mm | -55°C | +125°C | 12 Hours |

1 Maximum Gap Bridging capacity for RK-1300 and RK-1500 is 0.4mm with the activator applied to one side. 0.8mm if activator is applied to both.

Our Acrylic Adhesive Comparison Chart.

Our Acrylic Adhesive Comparison Chart.

To make finding the right acrylic adhesive a little easier, we've put almost all the specifications detailed on this page together into one comparison chart.

Of course, there's other details that may matter for your particular requirement. More information on all of these quality MMA glues is available on each of their product pages. We're also here to help. If you would like assistance in identifying the best acrylic structural adhesive for your application please do contact us and we'll do all we can to assist.

| Browse All Our Structural Acrylic Adhesives |